Our team of engineers will advise you on the most appropriate mooring option for your project.

Our unrivalled engineering capabilities mean we can meet the unique challenges of each location’s existing infrastructure, activity and environmental conditions.

Driven Piles

- Reduced sway movement of floating infrastructure; resulting in an improved fatigue life for joints

- Small overall marina footprint

- Piles can be external or internal in the floating infrastructure

- Reduced maintenance of floating infrastructure compared to mooring systems

- Pile brackets will be structurally designed to withstand all loading

- Wear Pads are fixed so that they are easily accessed for replacement

Quay Wall Piles

- Reduced sway movement of floating infrastructure; resulting in an improved fatigue life for joints

- Small overall marina footprint

- Piles can be bolted to a concrete/stone quay wall or welded to a sheet pile quay wall

- More cost effective piling option than driven piles

- Only suitable for pontoons, breakwaters are not normally restrained in this manner

- H Piles can be galvanised and/or painted for longevity

- Reduced maintenance of floating infrastructure compared to mooring system

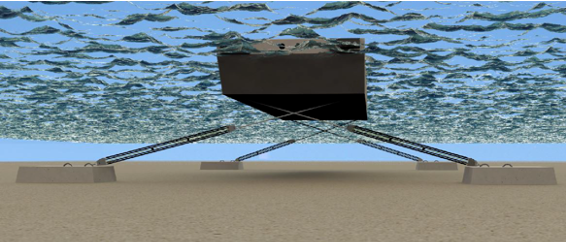

Mooring Options

- Arms are fabricated from galvanised steel for longevity

- Arms are hinged for the range of vertical motions

- Joints and arms are designed for the environmental and berthing loads

- Mooring Arms can also be used as access gangways

- A good alternative where either bed depth or material eliminates piles or moored options

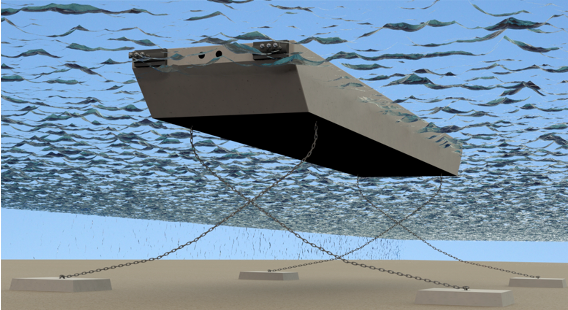

Chain Mooring System

- Weight of Chain in the catenary counteracts the environmental and berthing loads

- Chain can be held in place by gravity anchors or plough anchors

- Requires a large footprint

- The forces acting on the system are lower than a piled system as the pontoons can sway when impacted

- Can be a large range of motions

- We can provide a full mooring system design compliant with BS6349:Part 6

Elastomeric/Rubberised Mooring System

- Tensioned mooring system – rubber in the system extends when loads are applied

- A reduced footprint is required compared to a chain mooring system

- As the moorings are tensioned the range of motions are reduced compared to a chain mooring system

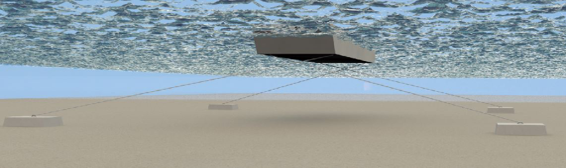

Rope Mooring System

- Tensioned system whereby the rope extends when a load is applied

- Ropes have to be installed at very shallow angles to achieve the required extensions; therefore, a large footprint is required

- Excellent solution where high environmental loadings are likely to be incurred

- Requires design by specialist engineers